The Storeroom Road Map Pt. 12: Final Thoughts

This blog series began as a 12-month effort to lay out a path to a world class storeroom. Together we’ve accomplished that. For this December issue, I’d like to offer some final thoughts and bring a few concepts home. I’ve appreciated the comments and replies as a result of putting this work together. These articles will be available for research for some time; please use and refer to them as long as it is helpful.

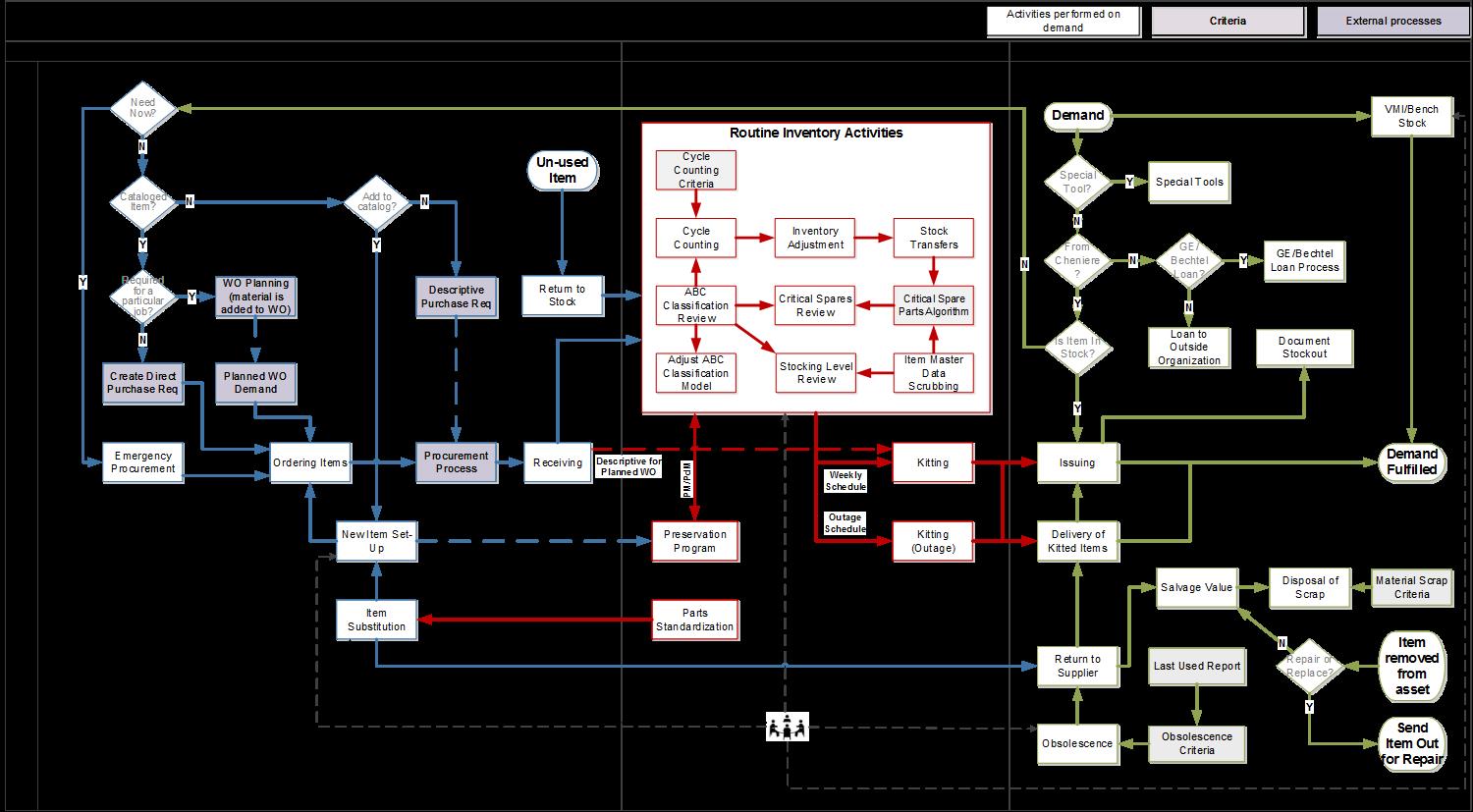

Now that you’ve been exposed to the concept of a road map, couple that with what you already know about work flow, and put together a process flow for the inputs and outputs of your storeroom operation. Here is an example: don’t worry, it isn’t intended to be viewed crystal clear; I just want you to get a sense of the scope of work the storeroom does and its interaction with everyone else.

Figure 1: Storeroom Workflow (example)

The process, practice, and KPIs that exist in the road map are present in the workflow above. Every organization will have a different arrangement to their workflow, but all will follow a common effort. Specifically, there are activities (shown as the columns in Figure 1) that address:

Procuring (getting stuff into the storeroom)

Storing and Maintaining (keeping stuff in the storeroom)

Releasing (getting rid of stuff from the storeroom)

I mentioned in the January 2015 blog (the first blog) that there are several KPIs that can be used to measure a storeroom’s performance: this is one area where more is not better. I suggest three simple metrics that really will tell the story:

- Inventory Accuracy (how well you’re controlling what you already have)

- Inventory Service Level (how well you are providing service)

- Inventory Turn Rate (how well you are using the company’s capital-$$)

With a listing and explanation of the process, practices, organizational requirements, and KPIs, along with the workflow example, you should be equipped to build your storeroom from the status quo to some desired state. I’m confident that many organizations can do this without much assistance. I do, however, recommend a first pass evaluation or assessment.

At Marshall Institute, we have a very comprehensive storeroom assessment tool used to determine exactly where a company is at a certain time. My colleague, Earl Porter, once told me as we were working on a maintenance assessment, “Even if you know where you’re going, you’re still lost if you don’t know where you are.” That makes a lot of sense.

Imagine setting off on a journey, your destination is known, or at least the intended destination is understood, but you don’t have any idea where you’re starting from. I’m not sure that you could ever begin that trip. Would you head North, East, South, or West? Chances are you won’t be taking the most direct route.

Our assessment measures every element we’ve been discussing this year, plus more. Our customers receive a very detailed report on where they currently stand, and a thorough strategic plan to move forward, on their journey.

Given the material that we’ve discussed in 2015, you are ready to perform an assessment on your own storeroom activities. I encourage you to do so. We are available to help if you feel a more learned assessment would be fruitful. We are also experienced in developing strategies to move ahead in almost every conceivable industry.

In order to have the energy and the interest to move from one level to the next, there has to be a compelling case for change. When I’m teaching, I talk about the two major elements that are needed for a compelling case:

- It has to make sense (cents, $$; as in ROI) to the company

- It has to answer WIIFM (What’s In It For Me) for the employee

If your business case doesn’t answer both of these questions, you most likely will not be successful in your change management efforts. A ‘compelling’ case excites people and makes them want to do what you need them to do.

You’ve no doubt heard that a “picture is worth a thousand words”: look at these two pictures:

Picture 1: Before (L) and After (R)

These two pictures are from the same place: this is a client of ours. Talk about your compelling case! Which image projects 98% inventory accuracy, 97% inventory service level, and a world class inventory turn rate?

I would submit that any organization can transform from the before picture to the after picture. Given enough ‘hands on deck’, this might be doable over the course of a single weekend. But longevity and sustainability require world class processes and practices.

The good news is that over the course of this year, each of you has been exposed to and given research information on providing the systems necessary to ensure sustainability. The storeroom is quickly being illuminated at the cornerstone in building an effective and efficient reliability program. How does your storeroom stack up?

Here in the 21st century, those that make no effort to advance their storerooms are making two bets: one, they already think they’re good enough, and two, they don’t think that they’re competitors are going to do it. I wouldn’t take that bet.

I’ve enjoyed sharing a year’s worth of thoughts with you. I’ve also been pleased with the feedback. I appreciate different views and ideas as well. One of the owners of Marshall Institute, Dale Blann, has said many times, “If you’re doing something that works for you, just get really good at it, then get better.” If you have a storeroom that works for you, just get really good at it, and then get better. Hopefully I’ve shared some ideas on how to do just that.